At Nordic Papers paper mill in Säffle (previous Peterson Scanproof) Birka Värme has the contract for operation of a 50 t/h boiler. To reduce the use of fossil fuel Birka Värme wanted to replace oil with wood powder. WTS AB got the contract for the conversion on the combustion side.

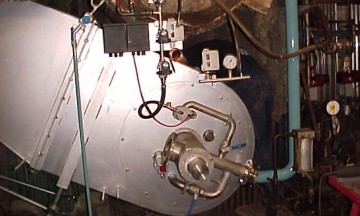

WTS AB have supplied, installed and commissioned all equipment for the conversion of the oil-fired steam boiler into wood powder combustion.

The system supplied by WTS AB includes an integrated fuel-storage with two milling lines and dosing system in a new house. A WTS multifuel wood powder burner replaced one of the existing oil burners. The combustion air system was used without any modifications.

The installation:

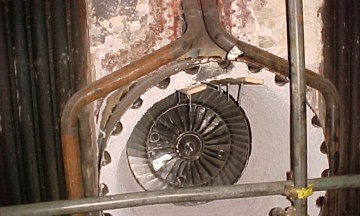

Trucks unload wood briquettes direct into the storage, in the storage wood briquettes for 72 hours can be stored. Hydraulic stokers feed the wood briquettes into a screw conveyer system. An intermediate storage is always kept full and from this storage, the wood briquettes are feed into two milling lines. Each milling line has a shredder and a hammer mill. Each milling line has a capacity of >3 t/h. The wood powder is stored in a dosing silo with a live bottom. The transport between the wood powder dosing and the burner is pneumatically.