The fuel is sander dust, saw dust and fine chips from the production of high quality hard wood floors. The fuel is milled in a hammer mill to uniform the wood powder to a maximum size of 1mm.

E-ON Sydkraft Värme Syd AB decided to install a new steam boiler for wood powder combustion.

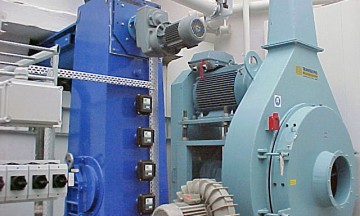

VTS AB received the contract for a turn key installation for all equipment between the existing silo and the existing electric precipitator.

The burner installation:

As start up fuel and back up fuel oil is used. Wood powder is produced in a hammer mill and stored in a 300m3 silo. The wood powder is screw conveyed into the dosing bin. The dosing bin has a live bottom. The live bottom is frequency controlled and the speed controls the flow rate of wood powder from the dosing unit. The wood powder passes a rotary seal and is pneumatically feed to the burner. The distance between the dosing unit and the burner is 70m. No pilot fuel is needed at any load.

The burner and boiler are fully automatic and are designed for 16 hours operation between visit by an operator.