How Multifuel Burners Are Reshaping the European Asphalt Industry

In a sector historically known for heavy energy use and fossil dependency, the European asphalt industry now stands at a crossroads. With mounting pressure from policymakers, investors, and end consumers alike, the question is no longer if but how asphalt plants can decarbonize—without compromising performance or process reliability. As it turns out, the answer might be simpler than many think.

The Shift Is On

Across Europe, initiatives are already reshaping how asphalt is produced. Hot Mix Asphalt (HMA) technologies are slowly but steadily being phased out in favour of Warm Mix Asphalt (WMA), making it possible to reduce energy demand by up to 20%1.

This transition is not just an environmental necessity—it’s an operational opportunity. And it’s happening right now, across Europe.

Meet the Burner Behind the Transition

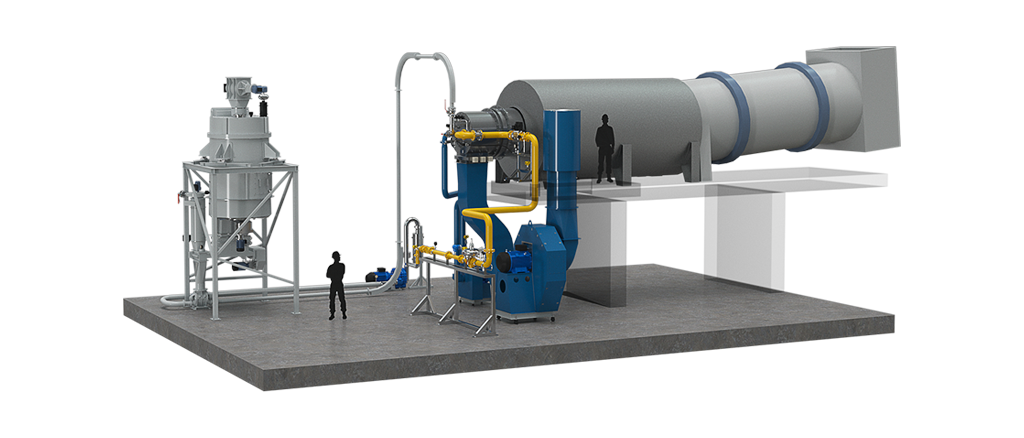

Behind many of these upgrades stands WTS, part of Swedish bioenergy innovator BK Tech Group. Their latest development: a multifuel burner system specifically tailored for asphalt production.

WTS has worked globally with combustion systems since 1989, with nearly 100 successful project deliveries. Now, their expertise is being concentrated on one of Europe’s most emission-intensive industries.

“Our high-efficiency multifuel conversion system, powered by wood powder combustion, enables the asphalt industry to transition to fossil-free operations—meeting future requirements and regulations with ease,” says Joakim Svensk, CEO of WTS.

What Makes It Different?

- Fully Automated, Fast Responding – Rapid load response ensures that performance and throughput stay optimal, even under fluctuating demands.

- Multiple Fuel Capabilities – Seamless switching between solid, liquid, and gaseous biofuels—including wood powder, bio-oil, and biogas—offers flexibility in a volatile energy market

- Low Emissions, Low Maintenance – With minimal NOx and CO emissions, and low operating costs, WTS technology meets the highest environmental standards while minimizing operational hassle.

- Output of up to 50 MW – One burner. Massive heat. Built for asphalt plants with serious production targets.

A Perfect Fit for Asphalt Plants

Asphalt drying is one of the most energy-intensive processes in the industry. In traditional rotary dryers, the aggregate mix is heated by direct firing, requiring immense and stable heat, in fact 100-150 °C for WMA and 150–200°C for WMA and HMA respectively. This is exactly where the WTS multifuel system shines. Its precise combustion control and adaptability make it ideal for both WMA and HMA production.

Add to that BK Tech Group’s proven track record in biomass-based steam systems—and you’ve got a decarbonization partner who understands heavy industry, not just clean tech.

Why Act Now?

- Stay Ahead of Regulations – With ETS2 and local CO₂ pricing mechanisms tightening across the EU, the economic case for action is stronger than ever.

- Meet Customer Demands – Contractors, cities, and infrastructure projects now require sustainable sourcing and climate declarations.

- Cut Emissions Without Cutting Corners – No compromises on uptime, capacity, or thermal stability.

“We know asphalt. We know combustion. And we know that the future of your industry depends on the decisions you make today,” says Joakim Svensk.

Ready to Make the No-Regret Move?

The future of asphalt is fossil-free—and it’s already rolling across Europe.