We Believe in Modern Combustion

Have you heard the claim that we must abandon combustion for better technologies? If so, it’s time to reconsider. Modern combustion, when paired with advanced filtration and cleaning, is as natural as breathing.

Every living cell on this planet relies on bioenergy combustion to survive – a process we call cellular respiration. It’s the same chemical reaction happening in our modern boilers, just at a significantly higher temperature.

Embrace this perspective, breathe easy, and join us in using renewable bioenergy to emit renewable carbon dioxide and replace fossil fuels with sustainable solutions.

Make the Switch to Bio Simple, Reliable and Future-Proof

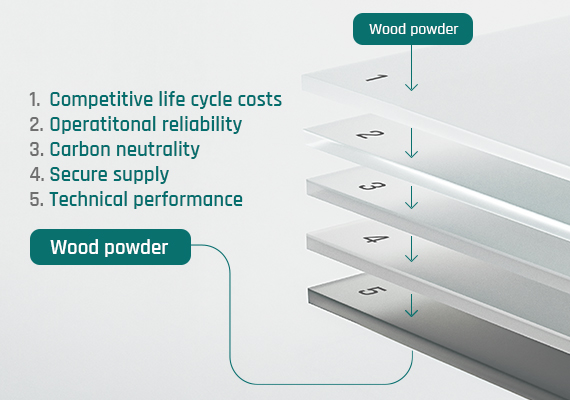

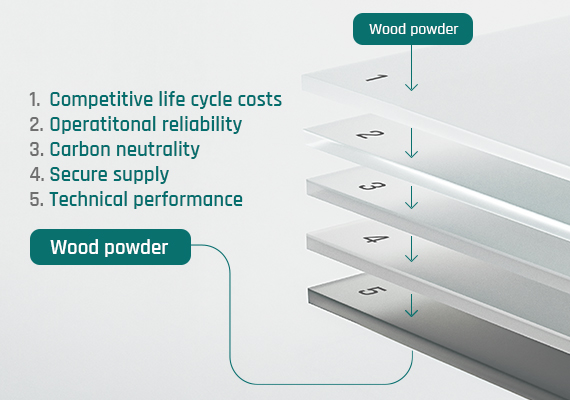

Wood pellets and powder are top-performing solutions for even the most demanding applications. With a proven track record and a decade of refinement for industrial use, pellets, and wood powder consistently deliver reliable performance and meet stringent technical criteria.

Biofuels offer the advantage of long-term availability and security, ensuring a sustainable energy source for the future. What’s more, with competitive Life Cycle Costs (LCC) that account for investment, operations, and fuel expenses, switching to bioenergy is a smart and cost-effective choice.

Your Choice of Fuel

We aim to help you decarbonize your processes and transition away from fossil fuels. Renewable options include biogas, bio-oil, and finely milled, dry biomass. With the advanced technology of WTS burners – whether all at once or step by step.

Discover which fuels are compatible with our burners and take the next step toward sustainability.

Be independent.

Be flexivative.

Fuel independence is key. That’s why you need the ability to use multiple fuel types – and sometimes even combine them – while switching seamlessly when needed. Our innovative technology delivers the ultimate flexibility. We call it being flexivative.

What type of fuels?

Powder

- Wood powder from pellets

- Wood powder from chipboards

- Wood powder from MDF

- Wood powder from flooring production

- Peat powder

- Soy hull powder

- Rapeseed hull powder

- Cocoa shell powder

- Meat and bone meal

- Cork powder

Oil

- Diesel oil

- Heavy oil

- Tall oil pitch

- Tall oil

- Light bio-oils

- Medium bio-oils

- Solvents

- Fish oil

Gas

- Propane

- Fossil gas (natural gas)

- Syngas from torrefaction

- Process gas

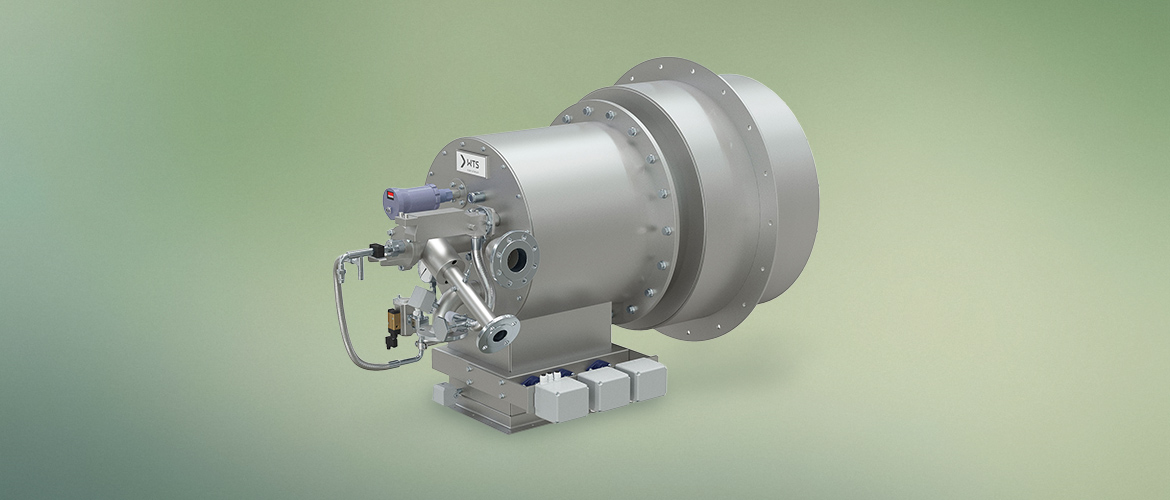

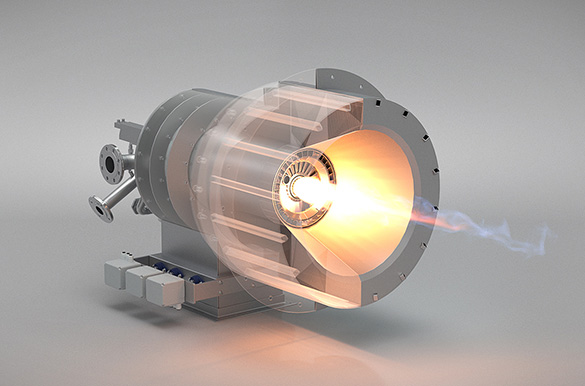

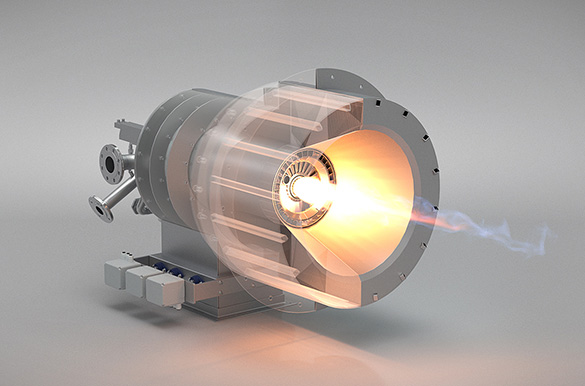

State-Of-The-Art Multifuel Burner

Crafted in Sweden, our state-of-the-art multifuel burners operate automatically and respond quickly to load variations. It delivers maximum flexibility and exceptional efficiency to meet your needs.

Your Roadmap to Decarbonization

We’re committed to making your journey to decarbonization seamless and secure. That’s why we begin this journey by understanding your unique challenges and needs, ensuring tailored solutions every step of the way. Below is a step-by-step outline of the WTS approach to guide you toward efficient and reliable decarbonization.

Step 1

Initial Meeting

We begin by gaining a comprehensive understanding of your business, current operations and energy consumption, as well as the challenges you face.

Step 2

Needs Analysis

WTS conducts a detailed analysis to recommend the multifuel system best suited to your business. Along with the recommendation, we provide an estimate of potential cost savings and emissions reductions.

Step 3

Multifuel Solution Design

Leveraging our expertise and experience, we craft the optimal solution for your operations.

Step 4

Engineering, Assembly, and Delivery

We manage delivery in its entirety – or specific parts – based on what works best for your project or needs. Regardless of the arrangement, we take full responsibility for our systems and accompanying control systems.

Step 5

Integration and Commissioning

We will ensure that the final work onsite will be performed efficiently, including the integration with your steam system. We’re always on-site during commissioning to ensure all parts work as they should. If any questions arise, or if you’ve chosen our Green Steam On-Demand option, we’re always at hand to answer them.

Do you have any questions? Get in touch with:

Joakim Svensk

CEO