Multifuel Burner System

Achieve maximum flexibility and fuel independence with our tailored systems and solutions. Designed to meet your specific needs and processes, every solution is built around our advanced multifuel burner technology.

Asphalt Industry

Asphalt Industry

A high-efficient conversion system powered by wood powder combustion, paving the way for a fossil-free asphalt industry that meets future requirements and regulations.

District Heating

District Heating

Smart, low-emission systems designed for district heating projects, delivering reliable performance for both peak and base load demands.

Drying Industry

Drying Industry

Our flexible and highly efficient systems are ideal for drying sand, gravel, cement, and clay as well as minerals, cereals and fodder.

Industrial Boilers

Industrial Boilers

High-efficiency systems designed for steam and hot water boilers, offering rapid load changes and adaptable solutions for modular or custom-built installations.

Fuel flexibility

Availability

High efficiency

Fossil-free

Fuel Flexibility

Our mission is to help you decarbonize your processes by transitioning aways from fossil fuels. Our technology supports renewable fuels such as biogas, bio-oil and finely milled dry biomass. Whether you’re ready to go fossil-free all at once or prefer a gradual approach, we have the solutions to match your pace.

What type of fuels?

Powder

- Wood powder from pellets

- Wood powder from chipboards

- Wood powder from MDF

- Wood powder from flooring production

- Peat powder

- Soy hull powder

- Rapeseed hull powder

- Cocoa shell powder

- Meat and bone meal

- Cork powder

Oil

- Diesel oil

- Heavy oil

- Tall oil pitch

- Tall oil

- Light bio-oils

- Medium bio-oils

- Solvents

- Fish oil

Gas

- Propane

- Fossil gas (natural gas)

- Syngas from torrefaction

- Process gas

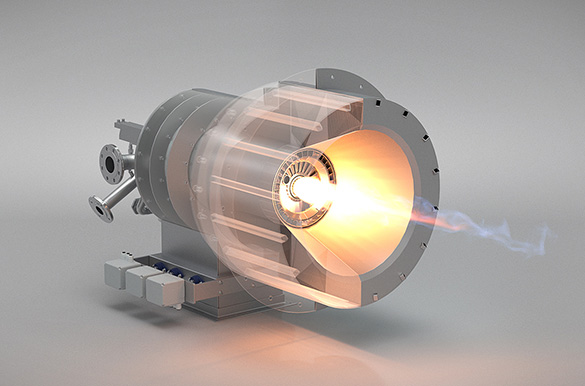

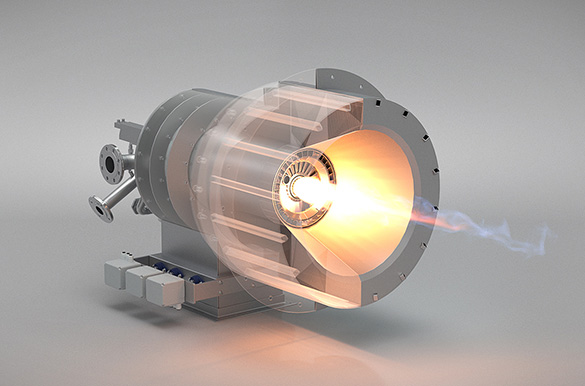

State-Of-The-Art Multifuel Burner

Manufactured in Sweden, our advanced multifuel burner is fully automated and designed for rapid response to load changes. It offers maximum flexibility and exceptional efficiency, making it ideal for your energy needs.

Dosage

The powder silo feeds the underlying dosing equipment, which precisely measures the required amount of powder for the burner. A blowing machine then transports the powder to the burner.

Combustion/Burner

The powder burner, designed for wood powder combustion, is integrated with your equipment. The system is equipped with fans and dampers for primary, secondary air control. A masonry burner cone is mounted on the burner for optimal combustion efficiency.

The burner includes an igniter for initiating combustion. The igniter’s flame passes through the register, lighting the starting fuel. The burner always begins operating using oil or gas before transitioning to powder combustion.

All media inputs are controlled by the oil/gas rack located near the burner, ensuring smooth operation.

Control system

The Multifuel Burner Control and Monitoring System (BCS) is engineered for optimal power management and system monitoring.

Go Multifuel. Go Green.

Be Flexivative.

Fuel independence is key – you need the ability to utilize multiple fuel types, even simultaneously, and switch between them seamlessly. Our innovative technology delivers the ultimate in flexibility, empowering your operations with sustainable, adaptable solutions.

We call it being flexivative.

Do you have any questions about our burners systems? Get in touch with:

Christer Rosendahl

Global Sales