Asphalt industry

Reshaping the asphalt industry with high-efficiency conversion systems powered by wood powder combustion. Our solutions help you transition to a fossil-free future, meeting the latest requirements and regulations.

Your needs

The European Asphalt Industry (EAPA) highlights wood pellets as a viable alternative to fossil fuels. Significant energy savings can be achieved by reducing production temperatures, for example, lowering from 180°C to 150°C – without compromising performance.

The process

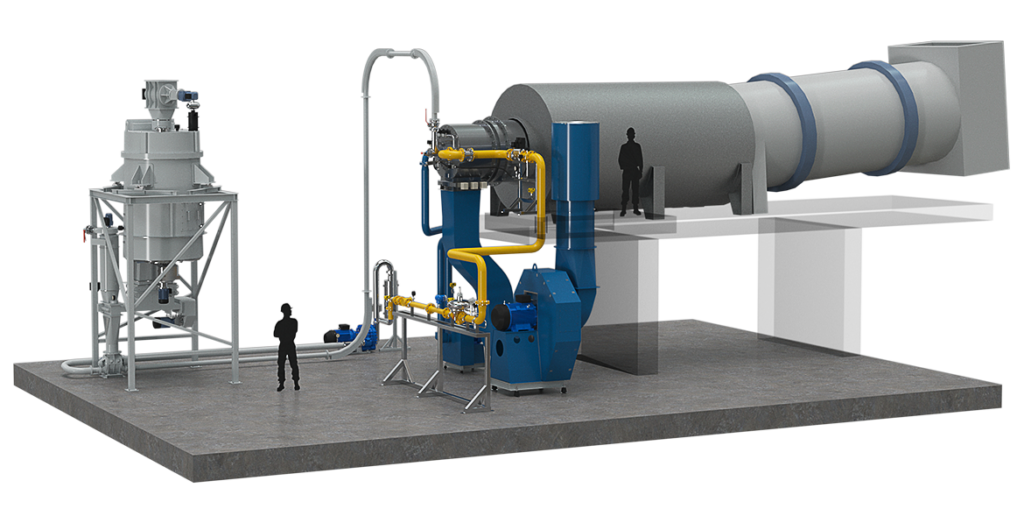

Hot-mix asphalt is prepared in a rotary dryer, heated to temperatures between 160°C and 240°C with direct burner firing. The asphalt is fed into the inclined rotary dryer, where it gradually moves toward the burner at the lower end. As it approaches the burner, the asphalt softens and becomes more flexible, achieving the ideal consistency required for road laying.

Our sulotion

Our high-efficiency multifuel conversion system, powered by wood powder combustion, enables the asphalt industry to transition to fossil-free operations, meeting future requirements and regulations with ease.

Do you have any questions about our burners? Get in touch with:

Christer Rosendahl

Global Sales